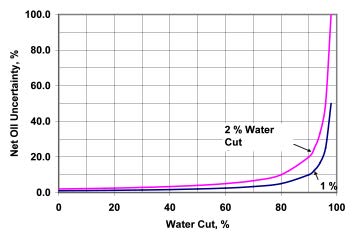

High water cut conditions can occur in water and steam flood productions as well as in mature reservoirs. Measurement uncertainty of Net Oil using a 2-Phase separator increases exponentially at high water cuts (>85%).

Enter 3-phase measurement

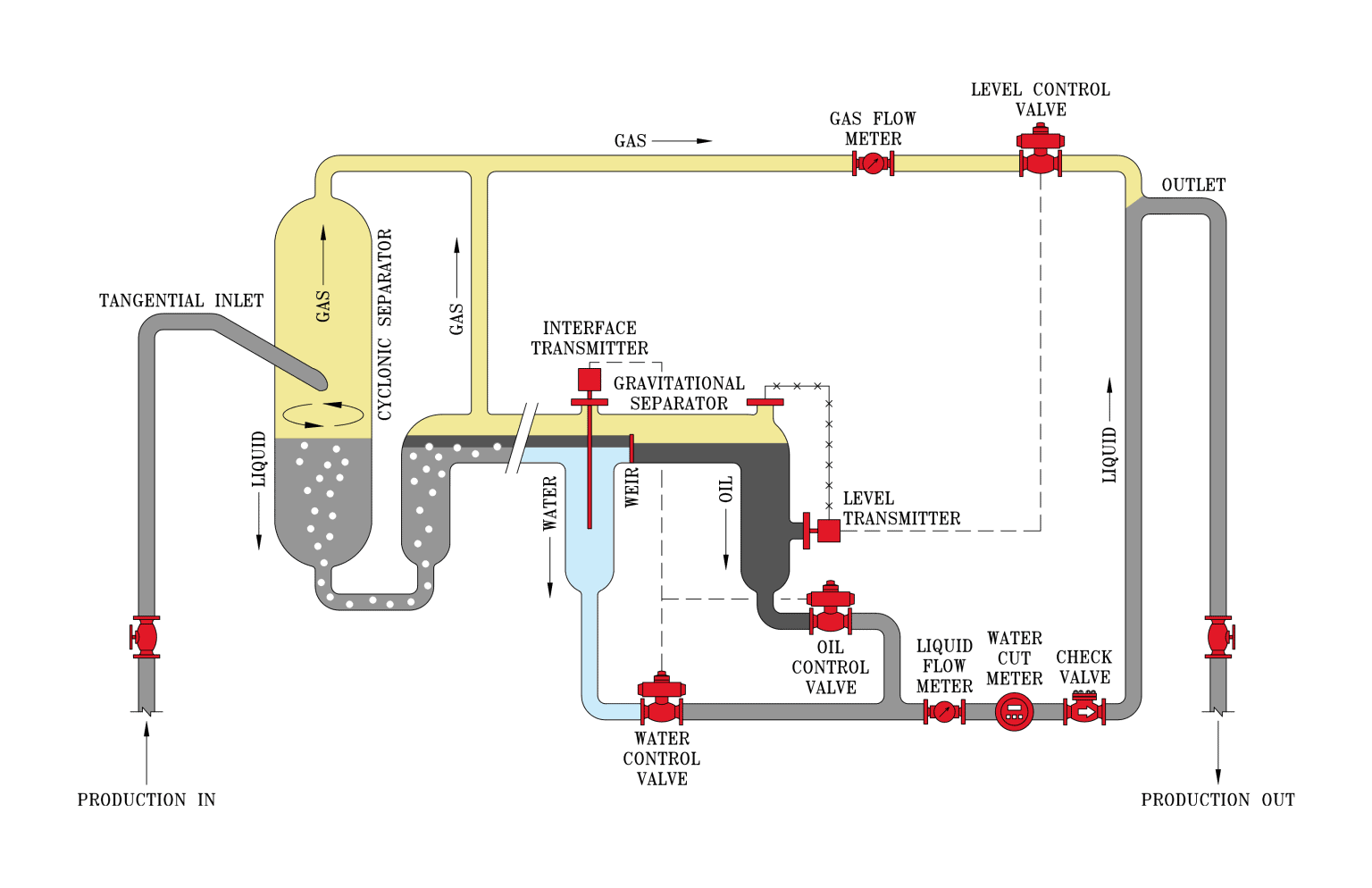

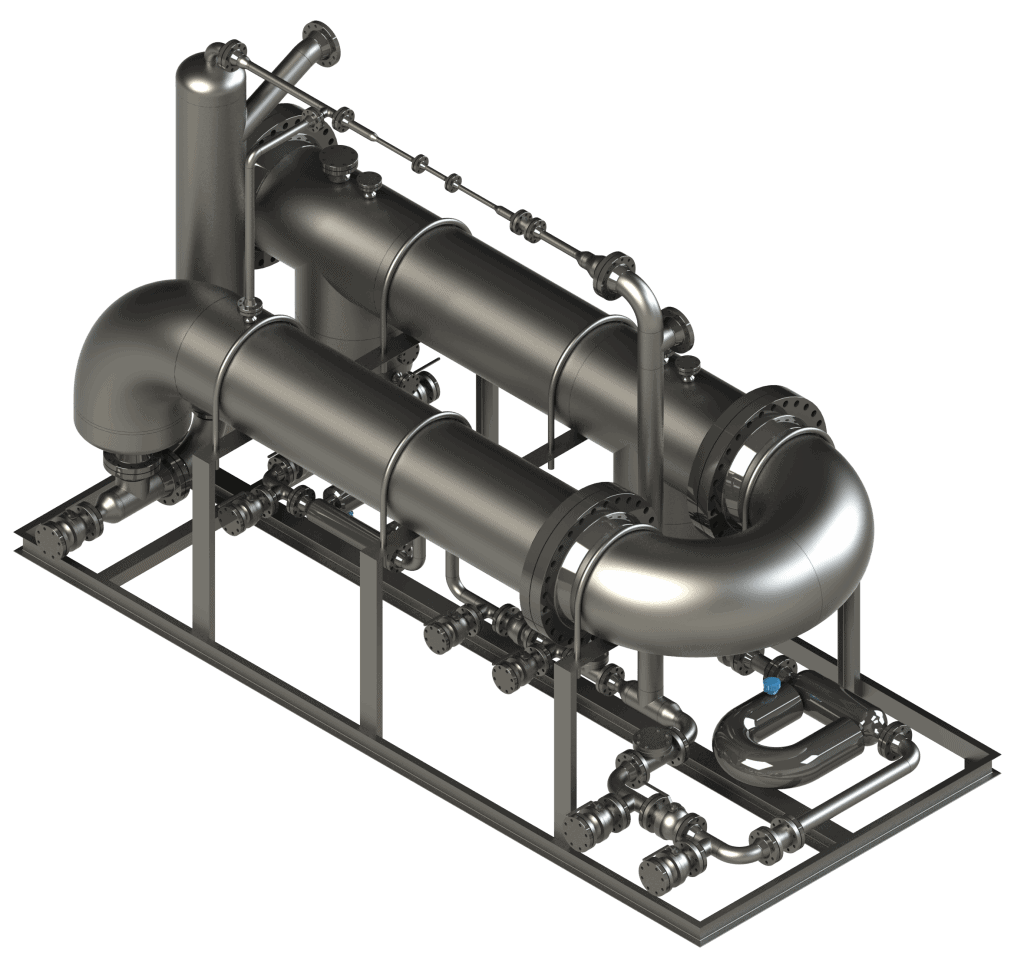

The Accuflow 3-Phase separation metering system addresses this issue of measurement uncertainty at high water cuts by taking an additional step of separating water from oil. The Accuflow 3-phase series consists of vertical pipe and a horizontal pipe sections connected together as shown. Production fluid (oil, water and gas) enters the vertical pipe tangentially, creating a cyclonic action in the pipe where the majority of the gas is separated and flows upward to the gas flow line above. The remaining gas, in the form of small gas bubbles, is carried under with the liquid stream and enters the horizontal pipe.

How It Works

As the liquid flows through the horizontal pipe, the remaining gas bubbles are completely separated. Meanwhile, the liquid phase is further separated by using a weir. The oil/water interface is controlled below the weir, allowing all free water to be collected in front of the weir. Oil is skimmed over the top of weir and collected behind the weir. The level of the interface determines the oil dump or water dump. This causes the free water to flow out from the waterline and be measured by the flow meter. The control process repeats, depending on the position of the oil/water interface. For liquid measurement, a Coriolis flowmeter and a capacitance-type water cut meter are typically used. For gas measurement, an ultrasonic meter, a vortex meter, or a Coriolis meter is typically employed.

Features

- Measurement uncertainties:

- Water cut / water-liquid ratio (WLR): 0.25% absolute

- Liquid flow rate: 0.25% of reading

- Gas flow rate: 3% of reading

- Works in 0-100% GVF and all flow regimes

- 100% separation efficiency and complete separation of the gas and liquid phases

- Less than 5 psi / 0.3 bar pressure drop across entire skid

- Uses the most accurate flowmeter technologies (Coriolis for liquid, ultrasonic for gas) with high turndown ratios (>100:1)

- Water cut determination and flow corrections to standard according to API MPMS, ISO, and AGA standards

Benefits

- Smaller, lighter, lower cost, and lower maintenance than conventional well test separators

- High quality, continuous well test data with extra diagnostic data for:

- Evaluating reservoir properties, well performance, and fluid characteristics

- Production optimization

- Reservoir modeling

- Guiding economic decisions

- AI/ML model training