The Accuflow 2-phase series is our main design and the most utilized.

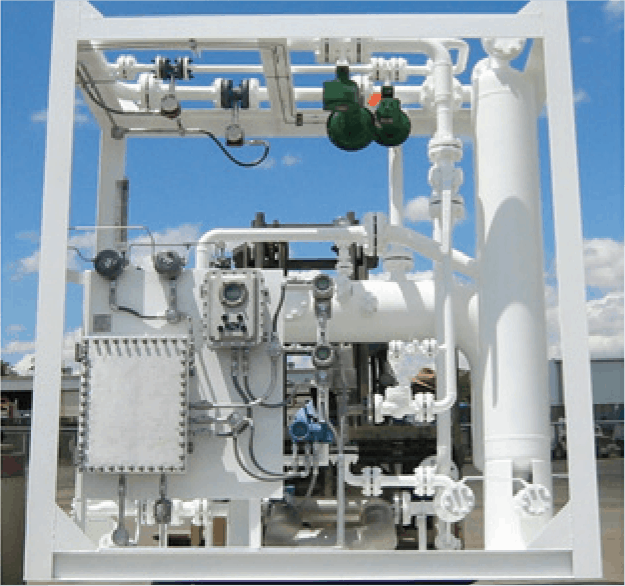

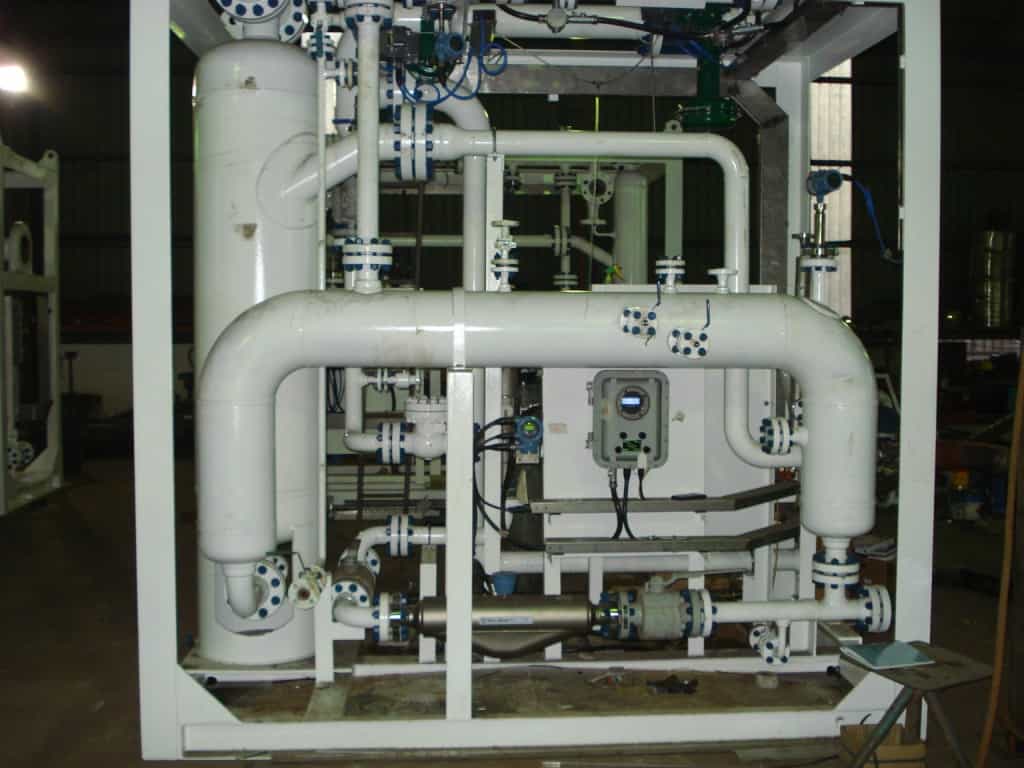

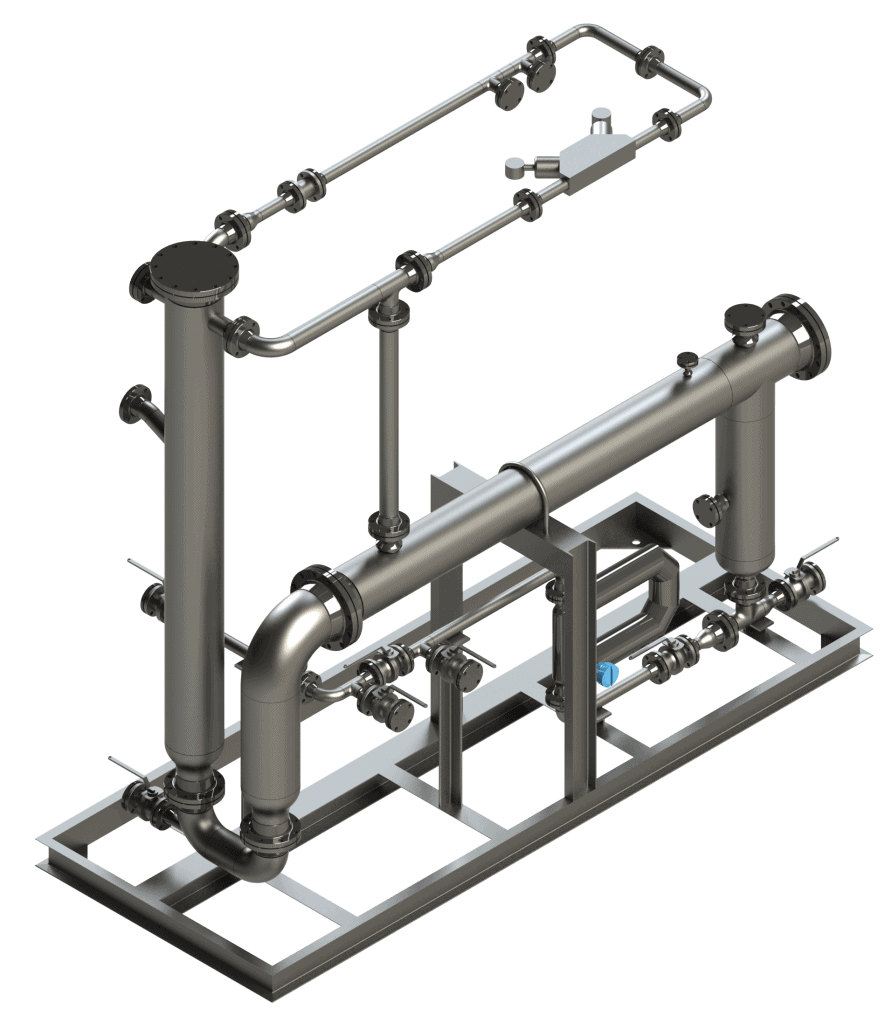

It covers low to high production flow rates as well as light to heavy crudes. It provides the greatest ability to separate gas and liquid. The footprint size can vary from application to application. We have the full SR version for the higher production flow rates and our more compact LT version for the lower to medium flows.

Every Accuflow skid is custom designed to meet your process measurement flow conditions.

How it Works

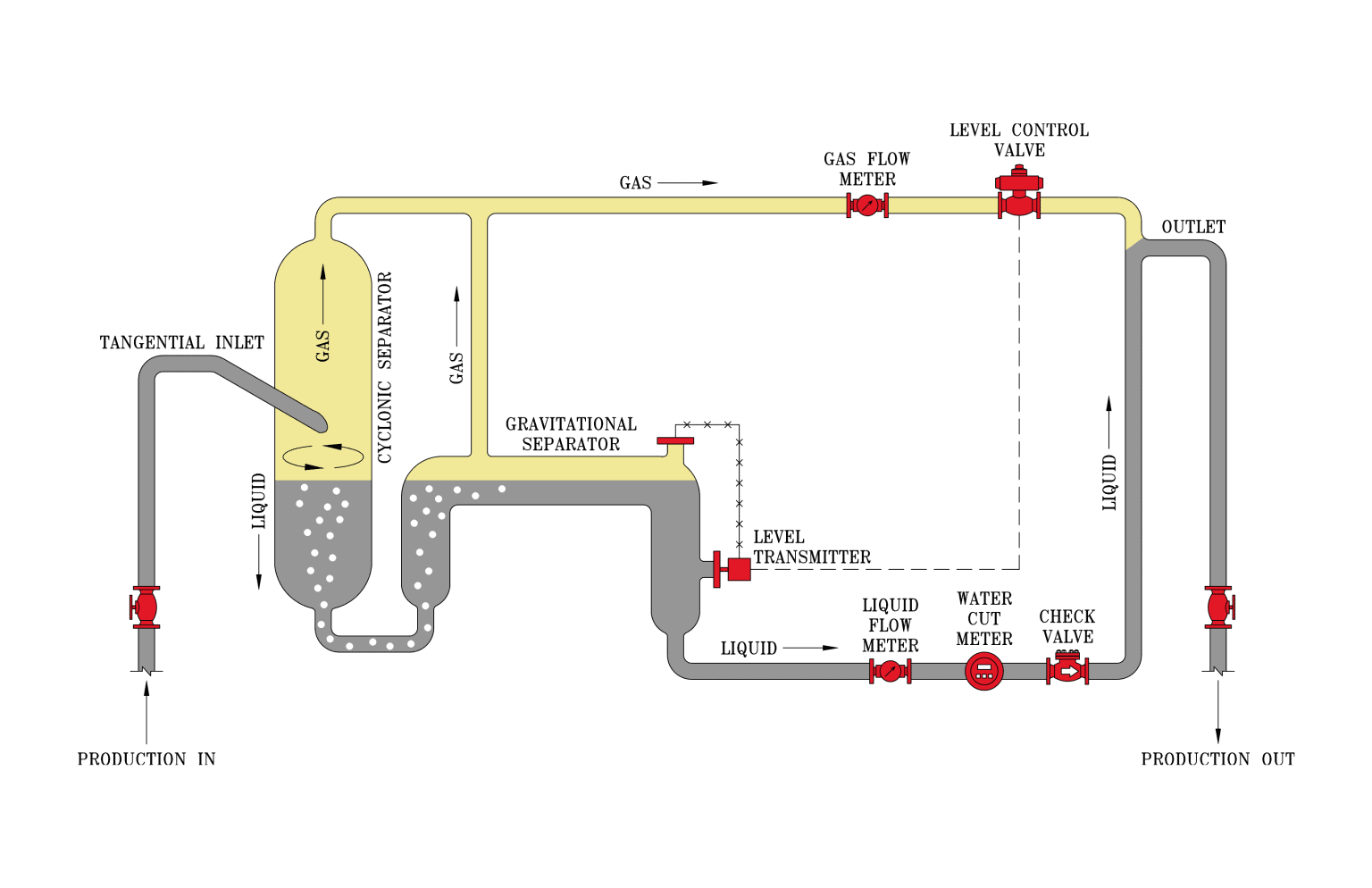

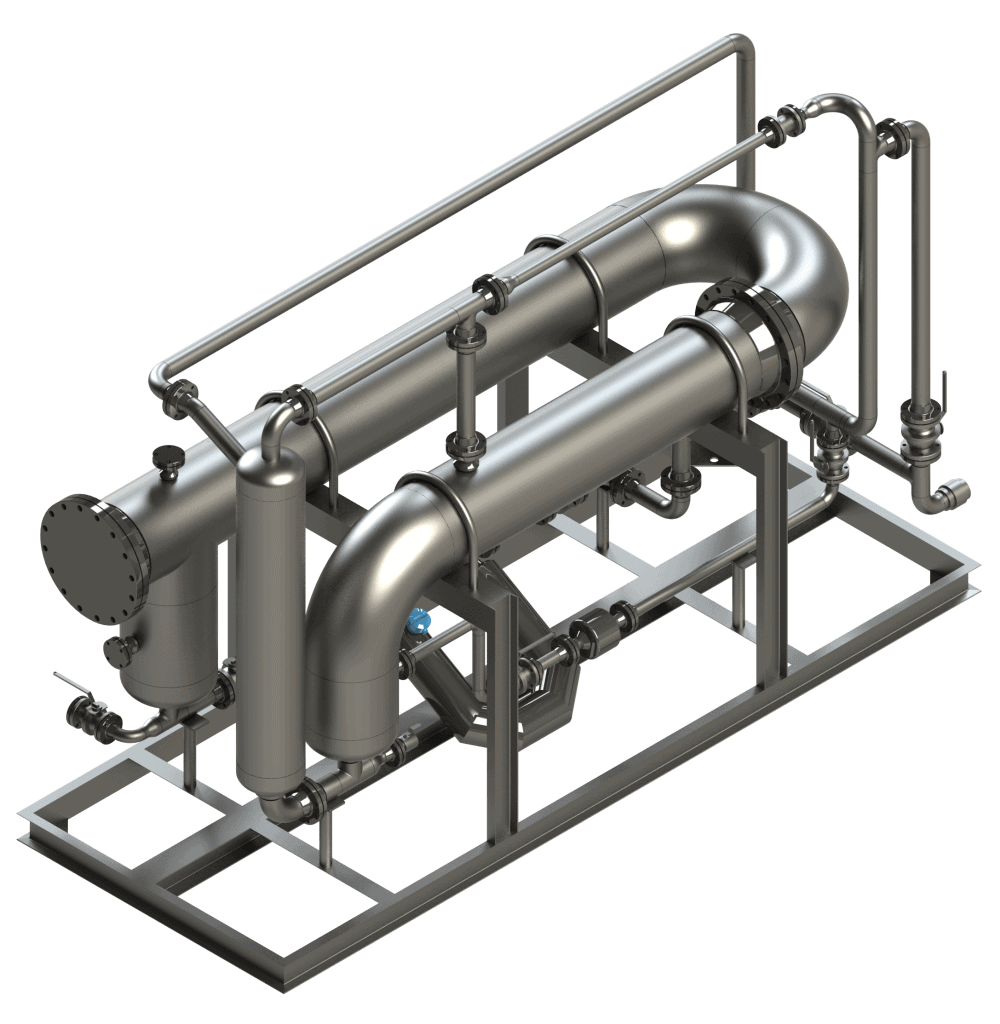

The patented Accuflow 2-phase series multiphase metering system consists of a vertical pipe section and a horizontal pipe section connected together as shown.

Multiphasic fluid (oil, water, gas) enters the vertical pipe tangentially, creating a cyclonic action in the pipe where a majority of the gas is separated and flows upward. The remaining gas is carried under the liquid stream (oil and water) and enters the horizontal pipe where the gas is completely separated.

Liquid level in the horizontal pipe is controlled at the center of the pipe using a control valve located in the gas flow line. Large gas/liquid interface area, thin gas bearing emulsion layer, and quiescent flow in the horizontal pipe, all contribute to efficient removal of free gas bubbles from the liquid stream.

About the meters

A conventional liquid meter (coriolis, turbine, etc.) is used to measure liquid flow rate. Water cut measurement can also be obtained using conventional technologies or methods (density differential, microwave, etc.).

Gas flow is also measured using conventional technologies (vortex, turbine, ultrasonic, etc.). After measurement, the gas and liquid streams are recombined and returned to the multiphase flow line.

The LT Series is particularly suitable for space limited areas, such as offshore platforms.

Features

Benefits

Anticipated Accuracy